Mechanical Engineering

Cost effective solutions for Future Mobility Systems

Chassis System

Mechanical Engineering department is working towards providing cost effective solutions, automation enhancement in design development activities and optimization solutions to future mobility systems. Our major work products are as below;

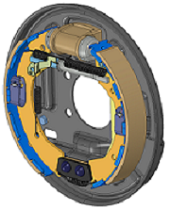

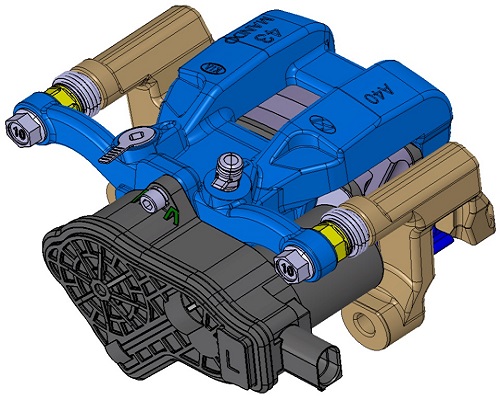

Conventional and Electronic Braking Systems

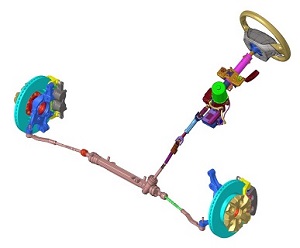

Hydraulic and Electric Power shaft steering systems

Conventional and Electronic Suspension Systems

E-Mobility Systems (Traction motors and Controllers)

Work Area

Design

Computer aided design (CAD) is a way to digitally create 2D drawings and 3D models of real-world products before they're ever manufactured. With 3D CAD, you can share, review, simulate, and modify designs easily, opening doors to innovative and differentiated products that get to market fast.

Key Functional Area

drum_brake_assembly

Motor on Caliper Assembly

- Design & Drafting

- Stiffness, FRF analysis

- DFM, DFA Checks, and Design Parameter Analysis

- Proto and Production Engineering Drawing

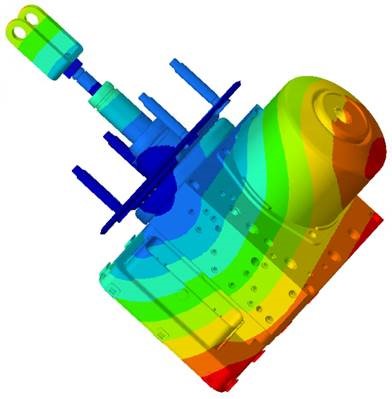

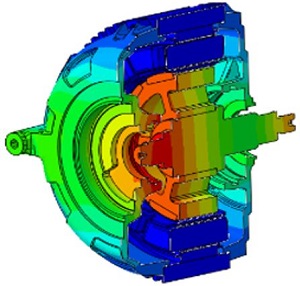

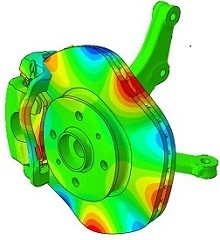

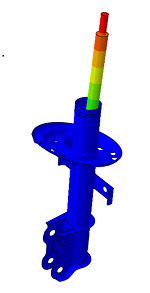

CAE

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes finite element analysis, computational fluid dynamics, multibody dynamics, durability, and optimization. To reduce the cost of prototyping, virtual models are developed and subjected to various real-time simulation conditions to check the structural integrity and feasibility of the product.

Key Functional Area :

IDB Assembly

Center Motor

- 2D and 3D FE Modeling such as Quad, Tetra and Hexahedral

- Stiffness & Strength Analysis

- Buckling & Large Deformation Analysis

- Fatigue Analysis

- Thermal & CFD Analysis

- NVH Analysis

- Squeal noise Analysis

- Correlational analysis with the test data for optimization

Automation

Automation is helpful in enabling shorter lead time, increase productivity, and improves quality, controlling human errors and produce cost effectiveness for work area of CAE & CAD process cycle. Automation generates Easy customization of software to meet end-user requirements & increased compliance to corporate processes through automation & this gives customer easy to use and work.

Key Functional Area :

IDB Assembly

- Pre and Post processing time reduction

- Design drafting

- Database management etc.

Work Products

Brake

Brake is an integral part of chassis system which is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction.

Key Products

Brake Corner Module

- Single Pot & Double Pot Calipers

- MoC, BIR, Monoblock Caliper, e-Drum

- IDB

- EMB Caliper

Steering

Steering is the system that steers the vehicle in the direction intended by driver. The steering system controls the directional movements of the wheel which control the stability of vehicle.

Key Products

CEPS Steering Column

- Column type (C-EPS)

- Rack type (R-EPS)

- Dual Pinion Type (DP-EPS)

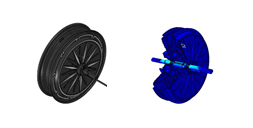

E-Mobility:

Electric vehicles (EVs) are driven by electric motors which are powered by energy stored in batteries. We design advanced powertrain solutions as per the vehicle dynamic and OEM requirements for all types of Traction Motors and Controllers for 2-Wheelers and 3-Wheels vehicles.

Key Products

Hub Motor

- Hub Motor

- Center Motor

- Motor Controller

Suspension

Suspension system consists of damper/shock absorber, spring and linkages that connects vehicle chassis and the wheel. The tuning of suspension system should compromise between road handling (braking, cornering) and ride comfort (noise, bump and vibrations).

Key Products

Suspension Strut Assembly

- Macpherson Strut

- Damper Assembly

- HCS, MFS & SFD Valve